Content

- How To Calculate Eoq Economic Order Quantity

- How To Calculate The Eoq Reorder Point

- How To Use Skubanas Economic Order Quantity Eoq Calculator

- Order Cost S

- What Is The Eoq Formula?

- Relevant Ordering Cost

- What Is Economic Order Quantity Eoq?

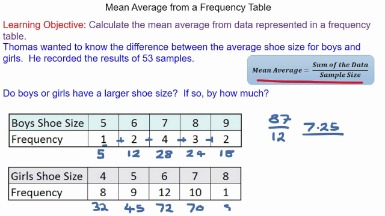

But to achieve cost efficiency and boost your profits, your company might need to make a few changes along the way. By incorporating EOQ into your operational strategy, your brand can not only reduce its overall inventory costs, but improve its inventory forecasting and eliminate stockouts, as well. The formula is the square root of (2 x1,000 shirts x $2 order cost) / ($5 holding cost.) This comes out to 28.3 with rounding. That means their ideal order size to minimize their costs while also meeting customer demand is a bit over 28 shirts. Since you cannot order .3 of a shirt, the minimum order could either be 28 or 29. Let’s take an example to calculate EOQ – Economic Order Quantity for a pen manufacturing company where the company’s annual quantity demanded is 400, holding cost is $2, and the ordering cost is $1. Calculating the EOQ for your business helps you find a good balance for your order and inventory costs, which are easy to overlook in day-to-day business.This is particularly so when the demand at the customer is itself uncertain. An interesting effect called the “reverse bullwhip” takes place where an increase in consumer demand uncertainty actually reduces order quantity uncertainty at the supplier. Economic Order Quantity is the ideal size of order that reduces the cost of holding adequate inventory and ordering costs to a minimum. This is one of the world’s longest used classical models for production scheduling. In the next step, HQ/2 translates to 281, and SD/Q also comes to 281. Using 187 for Q in the main relationship, we get a total annual inventory cost of $18,061, the lowest cost possible with the unit and pricing factors shown in the example above.If you’re constantly reordering products that don’t do well, the EOQ can help you determine how much to order to cover a specific time period. The EOQ helps companies minimize the cost of ordering and holding inventory. As explained by the economic concept known as economies of scale, the cost per unit of ordering a product falls, the larger the total quantity of the order. However, the larger the total quantity of an order, the higher the cost to hold and carry your inventory. The EOQ is a company’s optimal order quantity that minimizes its total costs related to ordering, receiving, and holding inventory. The goal of the EOQ formula is to identify the optimal number of product units to order. If achieved, a company can minimize its costs for buying, delivering, and storing units.

How To Calculate Eoq Economic Order Quantity

By integrating the EOQ formula with your ongoing inventory strategies, you’re bound to uncover some cash savings that can be used on other investments. At its core, cost efficiency is all about saving money — something every business from every industry can undoubtedly get on board with.Another important extension of the EOQ model is to consider items with imperfect quality. Salameh and Jaber are the first to study the imperfect items in an EOQ model very thoroughly. Overall, spending time to calculate your EOQ helps you make better decisions when it comes to managing and storing your inventory. The truth is that many businesses place orders based on a gut feeling of how much they need to order instead of ordering the product that is actually needed. Using your EOQ is a smart way to better understand how much you need based on three important cost variables.

How To Calculate The Eoq Reorder Point

They want to look specifically at a line of women’s shirts they’re carrying, to decide if there is enough demand to justify a larger order. Look at your historical data so you can determine how much of a product you sell year over year. Download the EOQ calculator and get one step closer to optimizing your inventory and building the business of your dreams. Inventory turnover is a financial ratio that measures a company’s efficiency in managing its stock of goods.

How To Use Skubanas Economic Order Quantity Eoq Calculator

Instead, organizations should speak to improve the way they order and pay for products with the use of the economic order quantity formula. Holding CostsHolding cost refers to the cost that an entity incurs for handling and storing its unsold inventory during an accounting period. It is calculated as the sum total of storage cost, finance cost, insurance, and taxes as well as obsolescence and shrinkage cost.

What is re order level of reorder period 25 to 30 days and?

A) Re-order level = Maximum consumption × Maximum Re-order period. 130 units × 30 days = 3,900 units.This guide will introduce you to the easy formula, how to calculate EOQ with an example, and the limitations you should consider when using the EOQ technique. Multiply the demand by 2, then multiply the result by the order cost. Janet Berry-Johnson is a CPA with 10 years of experience in public accounting and writes about income taxes and small business accounting.Using these insights, sellers can readily keep their products stocked, since Skubana automatically updates key values like sales velocity, reorder quantities, and forecasted reorder dates. Better decisions translate to increased sales, smoother fulfillment, and a more satisfied customer base. The cost per unit, or unit cost, never changes over the time period, even though the quantity of the order has changed. The EOQ always assumes that you’re paying the same amount per product every time. And also it seems that holding and ordering costs remain constant. There is a change in your employee salary, adjustments to your transport expenses, or increasing rent for your warehouse, these can all affect the cost and calculations that go into the EOQ. Your annual ordering cost or set up cost refers to the amount an order costs every time you buy it.

Order Cost S

By relying on Skubana’s handy EOQ calculator, your brand can save considerable time and money — two resources any and every company can benefit from having more of. When managing inventory levels, some items will inevitably need to be scaled back, while others will likely merit reordering . This ebb and flow can certainly present a challenge — but it’s one that economic order quantity is ready to tackle head on. Sometimes, it makes more sense for you to buy a product in bulk from a vendor to take advantage of a discount. In this situation, buying items in fewer installments actually optimizes costs, regardless of what the EOQ indicates. The EOQ lets you see how much you need to reorder and how frequently you need to place those orders.

What is the formula of minimum stock level?

(vi) Average Stock level = (Maximum stock level + Minimum stock level) x 14 or Minimum Stock level + 14 Reorder Quantity. Obviously, the Reordering level is below the Maximum level, and Minimum level is below the Reordering level and the Danger level is below the Minimum level. Safety Stock is above minimum level.It costs the company $5 to hold each shirt in inventory, and the fixed cost to place an order is $2. EOQ formula is used to minimize the cost of inventory and save cash. The sum of the two costs gives an annual total cost of an order. That needs to be calculated to find the best opportunity whether to store inventory or instead of it invest it somewhere else- assuming demand to be constant. However, as the size of inventory grows, the cost of holding the inventory rises. EOQ is the exact point that minimizes both of these inversely related costs. To learn more, check out the 8 best inventory management software in 2021.

What Is The Eoq Formula?

By calculating how much you need based on how much you sell in a given period of time, you can avoid running out of stock without having too much inventory on hand for too long. You may find that it is more cost-effective to order in smaller quantities. Calculating the EOQ for your business provides several benefits that impact your bottom line. It’s an excellent way to understand how much product you need to purchase to maintain an efficient supply chain while keeping your costs down. The below table shows the calculation of the combined ordering and holding cost at economic order quantity. Sometimes it makes sense for a retailer to buy a product in bulk from the vendor to get a discount. In such cases, buying items in fewer installments can actually optimize the retailer’s costs despite what the EOQ predicts.

- They want to look specifically at a line of women’s shirts they’re carrying, to decide if there is enough demand to justify a larger order.

- While this approach gets the job done, it isn’t the optimal way to do it.

- Using 187 for Q in the main relationship, we get a total annual inventory cost of $18,061, the lowest cost possible with the unit and pricing factors shown in the example above.

- The calculation also assumes that both ordering and holding costs remain constant.

- The economic order quantity, also called optimal order quantity, is the optimal number of products a business should include per order to reduce order costs, shortage costs, and storage costs.

To verify demand rate for your own business, you can look into a range of historical data, like turnover ratio, reorder points, and even purchase orders. With these insights in tow, you’ll have a good idea of the number of units you’re selling year over year, which will then inform your EOQ calculations . Inventory costs for ecommerce sellers are commonly referred to as carrying, holding, or storage costs, all of which increase in proportion to the amount of inventory you have on hand. In other words, having too much stock sitting around in your warehouse can significantly impact your bottom line (since you’ll still have to pay unit costs on unsold items). But when you leverage your company’s unique EOQ, you can avoid having a surplus of stagnant goods, and instead store the right volume of SKUs to effectively meet consumer demand.

Purchasing Cost Per Unit

Ordering cost is the cost of placing an order to the supplier for inventory. The number of orders is calculated by the annual quantity demanded divided by volume per order.The EOQ formula determines a company’s inventory reorder point. When inventory falls to a certain level, the EOQ formula, if applied to business processes, triggers the need to place an order for more units. By determining a reorder point, the business avoids running out of inventory and can continue to fill customer orders. If the company runs out of inventory, there is a shortage cost, which is the revenue lost because the company has insufficient inventory to fill an order. An inventory shortage may also mean the company loses the customer or the client will order less in the future.It is a measurement used in the field of Operations, Logistics, and Supply Management. In essence, EOQ is a tool used to determine the volume and frequency of orders required to satisfy a given level of demand while minimizing the cost per order.

What Is Economic Order Quantity Eoq?

Since carrying inventory is inherently expensive, ecommerce companies need to be incredibly careful with their number of orders and how they stock their warehouse locations. The EOQ formula is best applied in situations where demand, ordering, and holding costs remain constant over time. Assume that a company has steady demand of 12,000 units per year for one of its products.