Content

- How To Do Cycle Time Formula In Excel

- Project Deliverables: What They Are & Why They Matter

- Helps Improve Process Cycle Efficiency

- How To Measure Cycle Time

- Start Sleeping Right With Our Forever Warranty

- Preferred Calculation

- Production Time Calculator

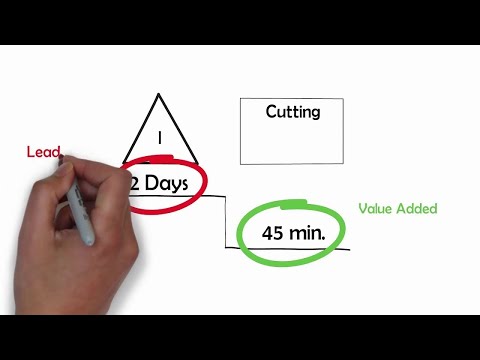

Lead Time Calculator in Excel — You can use this calculator to calculate your Lead Time, to understand how long customers usually need to wait from the moment they order a product. Production Lead Time — the time that elapses from the start of physical production to completed production. Your Customer Demand is the number of products your customers buy on a regular basis — usually, your customer demand is counted on a daily basis.Suppose you work at an organization and lead the internal marketing team. This year, you want your team to focus on building out your overall content strategy, which includes producing more online content and boosting your SEO rankings. With this in mind, one of the strategies you’re implementing is producing more blog content. But, industry aside, it also applies when managing projects of any size.The above example, however, is the simplest method for understanding average cycle time on a basic level. Now, Lead Time in supply management is the time needed to procure supplies that are vital for the production processes. Now, depending on the complexity of your production process, and whether you ship your products to distant cities or abroad, you can also count your Lead Time in hours or days.

How To Do Cycle Time Formula In Excel

Here, his cycle time is the amount of time he takes to cook one meal. And since they’ve just discovered fire, it’s going to speed up the cycle time. This way, his cycle time per meal goes down and he can feed more customers. Additionally, collaboration is a necessary component of optimized workflows, and Wrike has you covered. Wrike integrates with over 400+ leading software providers, which means you can optimize your production workflows without having to leave behind the tools you already know and love. Then, you can use the time tracker feature and have your team members calculate the actual amount of time they’re spending on each task. To measure and report on the estimated time it will take to complete a task, you can set up a custom field and have your team members enter the estimated time for a task.

Project Deliverables: What They Are & Why They Matter

Use our log splitter speed calculator to figure out how fast your splitter will cycle! Using processing conditions input by the user, the estimator outputs a conservative number that represents the cycle time for a number of resin families. The calculation is based on standard theoretical thermodynamic equations, which take into effect the thermal diffusivity of the various materials.

- Since cycle time represents the processing time of a specific product, it also includes any time lags or pauses that happen either intentionally or as a result of an error.

- In line with that, finishing 1 product every 2 hours is your takt rate.

- Theoretically, the machine can produce 12 parts, but you don’t need that many.

- You can use the list below as a cheat sheet to convert the various formulas into parts per minute.

- Using processing conditions input by the user, the estimator outputs a conservative number that represents the cycle time for a number of resin families.

- We’ve rounded up the fundamentals of cycle time, its benefits, two other formulas it works alongside, how it should be calculated, and how to track it.

This is where it’s essential to understand what you’re actually measuring and why. There are typically 3 terms used to represent a cycle time, and as we said before, defining those terms varies from manufacturer to manufacturer. Finally, OEE is calculated by multiplying the three OEE factors. If you do not directly track Good Count, it also needs to be calculated. What your OEE score doesn’t provide is any insights as to the underlying causes of lost productivity. This is the role of Availability, Performance, and Quality.

Helps Improve Process Cycle Efficiency

The orange portion for example #1 is likely what you, and many other manufacturers, think represents the cycle time. You could make 200 parts, but you probably didn’t take into account the manual actions the operator needs to do to get it up and running in the first place. If that’s the case, you will have over-estimated the amount of product that can be made in a given period. You need to add allowances to the average cycle time to estimate the production capacity more realistic. As you know, when you do cycle timing of an operator, she would have been working for her bundle and stitched few garments one after another without taking a break.

How To Measure Cycle Time

By understanding the time component more thoroughly, the carpenter can decide how many chairs he wants to produce and how he should price them. Time is directly connected to several key performance indicators that measure a company’s ability to produce, grow, meet customer demands, and maximize results. Cycle time is one metric that allows manufacturing leaders a chance to learn more about productivity. Say that your pre-processing time involves receiving the orders, reviewing the number of orders for that day, and making sales requests to your production team. You track time on all these activities and see that they take 10 minutes to complete for each order. Roughly speaking, this pre-processing time involves Order Handling Time and Manufacturing Lead Time. Working on a complex project that may include multiple cycle times as your team works through each stage of the project lifecycle?

Start Sleeping Right With Our Forever Warranty

The rest of this resource serves as an explanation of cycle time and why the definition often varies. Then, we’ll dive into using an ideal cycle time on the floor to monitor machines and the production process. Cycle time is a contentious topic, not because it doesn’t provide value to manufacturers, but because the definition of cycle time is widely debated.Although the cycle time calculation is not one that the average consumer needs to grasp, it’s an especially useful metric if you run a production line. Even small and home-based businesses can benefit from understanding how long it takes to produce a single item for sale. Next, consider a large fashion company that manufactures thousands of articles of clothing to sell to customers around the world. An ideal cycle time is also important for this type of business since it needs to determine an appropriate batch size for each fashion season and geographic market. In this scenario, the company may need to determine the best unit of measure for its particular products and production needs in order to stay profitable.

Production Time Calculator

Cycle time calculators are available to download and are divided into 10 types of files for different actuator types. Since cycle time is relevant to many industries, the possible examples are nearly endless. Decision-makers can gain a complete picture of whether the item is priced reasonably given the time it takes to create it. Let’s say that it’s January and that you’re looking at 31 days before the next reordering — 31 days is your reordering delay. Currently, with a Cycle Time of 12,22 minutes, you’re running 2,22 minutes behind for each doll — considering that your Cycle Time is longer than your Takt Time. In line with that, Cycle Time is the average amount of time you need in order to produce one unit.The rate at which your team produces a product, project, or deliverable matches the customer demand you’re up against. If your cycle time exceeds your takt time, your customers will be dissatisfied because you can’t keep up with the demand.Marija Kojic is a productivity writer who’s always researching about various productivity techniques and time management tips in order to find the best ones to write about. She can often be found testing and writing about apps meant to enhance the workflow of freelancers, remote workers, and regular employees. Appeared in G2 Crowd Learning Hub, The Good Men Project, and Pick the Brain, among other places.

How Do You Calculate Cycle Time?

Sometimes, the start of Task 2 will depend on and won’t be able to occur before the completion of Task 1. Each new shipment of fruits takes 5 days to arrive — this is your supply delay. Mathematically speaking, Lead Time is the sum of the supply delay and the reordering delay that may occur from the moment you order the supplies, to the moment you receive them from the supplier. Order Handling Lead Time — the time that elapses between the time you receive the order and the time when you create an official sales order request. So, according to this calculation, Team #1 is expected to assemble one Doll #1 per 10 minutes , in order to meet the Customer Demand. As you update these estimates, ClickUp will update your delivery date in real-time too.You manage to deliver bundles of mail to 300 addresses during your 10.5 hour production time. Using this information, you can now build in the total number of hours needed to generate blog content into your team’s schedule and do a more effective job building out your content strategy. Cycle time can be applied across a broad range of industries and types of work. In software engineering, it refers to how long it takes to deploy code, or in supply chain management, it can explain how long it takes to fulfill a product order. This is all very important because, in the end, customer demand enables manufacturers to appropriately schedule production. The images below provide a visual representation of why measuring the cycle time of a process is more valuable than measuring just the machine cycle.Example #2 is good for making estimates because it shows how fast you are capable of running , and will, in turn, give you a target cycle time that is easier to hit and measure. Then, you can use that number to calculate how much product you’re actually making and if there are problems or issues that need addressing.A cycle time is a measure of how long it takes to produce a given part. As a manufacturer, if you expect customers to go through X amount of product, you need to figure out how often you have to run the job, per day, in order to meet that demand. When you look at the complete process, this helps you estimate how many parts you can make in a day, realistically. You don’t really want to use the machine cycle because it will give you an overly optimistic view that you’ll never be able to hit. These are all questions you can ask yourself to get to the root of the problem. And without calculating cycle time, you would be left in the dark about where the problem truly lies. The company you work for makes desks for elementary schools.Now imagine when your alarm goes off Monday morning and how hard it is to get out of bed. The interesting thing is that it’s not necessarily because you got less sleep. In fact, it has more to do with where you are in yoursleep cyclewhen you wake up.Unfortunately, not all manufacturers and business leaders define this metric in the same way. This is not to say that cycle time isn’t valuable, but that each separate entity follows its own rules and definitions. Since cycle time represents the processing time of a specific product, it also includes any time lags or pauses that happen either intentionally or as a result of an error.Without this metric, business leaders may not have a true understanding of how much time it takes to produce a single item for sale. Average cycle time is important because it provides insight into the productivity of a manufacturing system. This is true for large corporations, midsize production teams, all the way down to solo entrepreneurs who manufacture products in the comfort of their own homes. Although it’s not a physical good, time is a valuable resource in business, production time, and life in general. Anyone involved in manufacturing understands how impactful time is to productivity and to a company’s bottom line when managing costs and revenue. Sign up for a free trial of Wrike and start optimizing your workflows and boosting customer satisfaction today. Cycle time isn’t just a measure of how much you’re producing — it’s a metric that will help you deliver high-quality work and leave you with loyal, satisfied customers.If you lack a clear understanding of how long it takes for your team to complete specific tasks in their work, it’s challenging to scope work accurately with your customers. This leads to frustration on your team when they realize a project is way more than they bargained for, as well as with your customers when they realize you need to push out your deadline. Cycle time will give you a more accurate project scope than simply taking an educated guess. When you have an in-depth understanding of your production flow, you can implement processes and tools to ensure consistent production rates.By honing in on your production rate to standardize it, you’ll eliminate the chances of under and overproducing. You thought a specific task would take 40 hours to produce from start to finish, but your team says it will take at least 80 hours to complete that task. Consider a pharmaceutical company producing product in batch format. The cycle time is normally calculated as per the continuous process previous, however, the batch is considered the unit of measure, so that the cycle time is given as a batch cycle time. Enter the total number of parts produced and the total production time into the calculator to determine the cycle time. The ideal cycle time, not the theoretical maximum of the machine, will help you determine how best to measure and utilize the machine on your line.